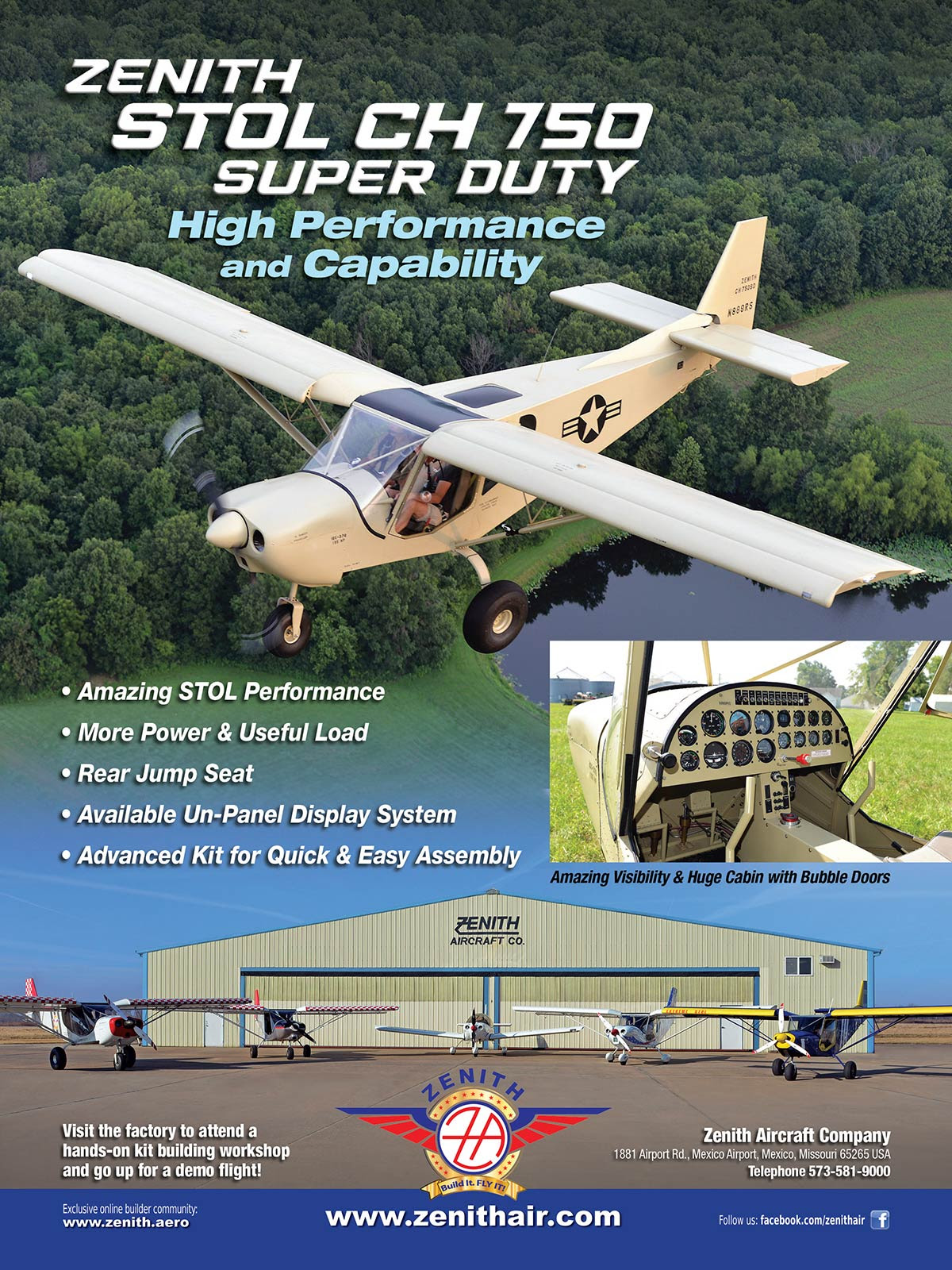

Randy Shannon’s STOL CH 750 SD. Read the 12 months to take off article in Kitplanes. Click here.

Like its predecessors, the STOL CH 750 offers extraordinary STOL performance." — Ed Wischmeyer, In Flight USA, October 2022

" Zenith is always working to make their kits easier to build and the CH 750 is the easiest yet." — Ed Wischmeyer, In Flight USA, October 2022

The above video is of the STOL CH 750-SD wing assembly. All the CH 750 models are similar in design and as easy to assembly.

The above video. Building the CH 750 Super Duty complete rudder assembly.

The above video is of the new CH 701 fuselage assembly. Note that all the CH 750 fuselages are matched-holed and as easy to assembly as the new 701.

As a kit aircraft, the builder retains complete control of the “homebuilt” aircraft project, choosing the engine and propeller, panel and avionics, wheels and more. The builder can truly build an aircraft to suit their needs and requirements, determining the features (and budget) of their aircraft.

[Above photo: Jan Eggenfellner with his Viking (Honda) powered custom-built STOL CH 750 Super Duty.]